Lagering is a critical step in producing clean, crisp lagers with a refined taste and smooth finish.Techwin limited offers lagering tanks that

are specifically designed to support the extended cold conditioning required for traditional and modern lager styles. Built to the highest standards of hygiene and efficiency, these tanks offer precise temperature control, superior clarity, and long-term storage capacity.

Product Description

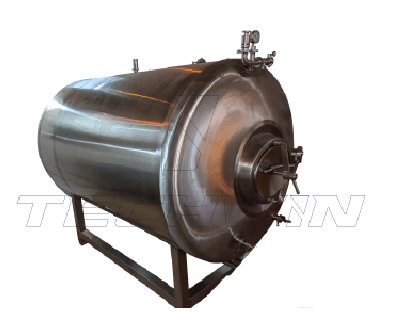

Our Lagering Tanks are horizontal or vertical stainless steel vessels built to hold beer at near-freezing temperatures over extended periods. This maturation phase allows for yeast sedimentation, flavor smoothing, and carbonation stability. Available in a range of sizes and configurations, our lagering tanks are fully jacketed, insulated, and customizable to suit breweries of all scales.

Key Features

• Stainless Steel Construction

o Made from food-grade SS304 or SS316L

o Interior polish ≤ 0.6μm Ra for easy cleaning and sanitation

• Glycol Jacketed Cooling Zones

o Multi-zone dimple jackets ensure uniform cold storage

o Efficient insulation maintains stable low temps (0–4°C)

• Horizontal or Vertical Design

o Horizontal tanks offer better yeast sedimentation and space efficiency

o Vertical tanks ideal for smaller spaces or specific brewery layouts

• Pressure Rated & Carbonation Ready

o Tanks rated for low to moderate pressure (1.5–2.5 bar)

o Equipped with carbonation stone for optional in-tank conditioning

• CIP-Compatible Sanitary Design

o Built-in spray ball and CIP arm for automated cleaning

o Easy-access manway for inspection and manual maintenance

• Multiple Valves and Ports

o Sampling valve, racking arm, drain valve, and pressure relief valve included

o Thermowell and optional digital temperature display

Benefits

• Promotes flavor stability and smooth mouthfeel

• Allows for natural clarification and sedimentation

• Enables long-term cold storage and lager development

• Reduces diacetyl and other off-flavors

• Ideal for carbonating, clarifying, and storing lagers and other cold-conditioned beers

Applications

• Craft and Microbreweries

• Regional and Commercial Breweries

• Brewpubs & Taprooms

• Lager-Specialty Breweries

• Pilot Breweries Needing Cold Conditioning

Technical Specifications

Specification Details

Capacity Range 500L – 10,000L

Tank Orientation Horizontal / Vertical

Material SS304 / SS316L

Pressure Rating 1.5 – 2.5 bar

Insulation Thickness 80–100 mm Polyurethane Foam

Cooling Jacket Zones 1–3 (based on size and configuration)

Surface Finish Interior ≤ 0.6μm Ra; exterior brushed or matte

Manway Type Top, side, or end-mounted

Carbonation Stone Optional (removable, CIP-capable)

CIP System Built-in spray ball + CIP port

Mounting Option Adjustable feet or skid-mounted

Ports Sample, racking, drain, PRV, CO₂ inlet

Optional Features

• Horizontal stacking system for space optimization

• Sight glass or level indicator

• Digital temperature controller

• Load cells for weight monitoring

• Mobile tank option (casters for pilot setups)

• Custom brewery branding or finish

Why Choose Our Lagering Tanks?

• Optimized for long-term beer maturation and storage

• Crafted to meet global brewery hygiene and safety standards

• Modular design for easy expansion

• Efficient cooling system for energy savings

• Trusted by lager producers worldwide

Get Lagering Right

Elevate your lager production with professional-grade lagering tanks tailored to your brewing goals.

Contact Techwin limited at 0719 034 950 for a custom quote, brewery integration plan, or technical consultation.