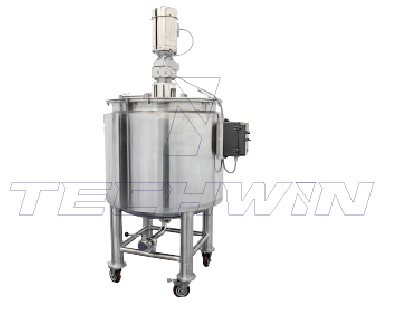

Our mixing tanks are tailored to solve individual customers' process and storage challenges

therefore they are custom-made with your needs in mind. Whether standard or custom, our engineers design and manufacture stainless-steel mixing tanks suitable for a wide range of applications, including ingredient mixing in the brewery industry.

Customized to Meet the Individual Client’s Specifications, Considering Factors Such as:

- Size and geometry of the tank.

- Viscosity of the processed product.

- Level of sanitation required for interior welds (100% sanitation).

- Ease of cleaning (CIP) requirements.

- Processing function of the tank, including heating and cooling requirements.

- Size and quantity of mix impellers required for the product.

- Pressure requirements during processing.

- Mixing speed requirements.

- Heavy duty food grade non-corrosive stainless steel 316 or 304 grade depending on the use.

- SS fittings are 316 or 304 grade depending on the use.

- Pressure tested and passed through continuous quality control measures.